Electrical Maintenance Can Save You Money

Consider the risks associated with electrical appliances

Regular electrical maintenance not only keeps your property safe, but it also comes with a lot of added benefits. Having an established maintenance routine on all electrical fittings and devices improves their performance while creating a safe environment that is free from any forms of danger.

Poor or insufficient electrical maintenance can cost your business both time and money. According to the Electrical Regulatory Authorities Council, in Australia, 20 deaths occur each year from electrical related accidents and 1065 hospitalisations are caused by electrical related injuries. 69% of these deaths were classified non electrical workers or the general public. Statistically, 65% of the injuries relate to appliance/equipment problems. Help prevent these risks by implementing an electrical maintenance plan.

Unplanned Repairs

Safety Risks

Electrical safety should be treated as a necessity. There are many risks associated with electrical equipment. The most common are exposure to live parts, shock and burns, as well as fire or explosion. An Electrical maintenance plan will prevent these risks.

Compliance

We don’t often consider the possible danger associated with electrical appliances. Regular testing and inspection is a necessary compliance requirement and varies from state to state. If you don’t adhere to the legal requirements you could face hefty fines.

Inefficiency

There are many ways to improve energy efficiency. A regular maintenance plan will point out electrical leaks, outdated lighting and high consumption appliances. If you reduce your energy expenses you will increase profitability.

Steps in setting up a maintenance plan

- Acknowledge your current situation in terms of electrical maintenance, breakdowns and repairs to better understand the costs and down time.

- List and perform a critical analysis of the electrical assets, determine which equipment is priority and which are prone to failure.

- Assess which failures are preventable and which are typical of the equipment in question. If possible, gather history on equipment failures.

- Understand the amount of downtime is required to check each unit and what the implications are.

- Understand what replacement materials you may need to keep in stock. Materials should be listed against the equipment so that it can be easily identified and ordered.

- Work towards fine tunning the maintenance process. Keep notes and capture feedback to improve maintenance initiatives.

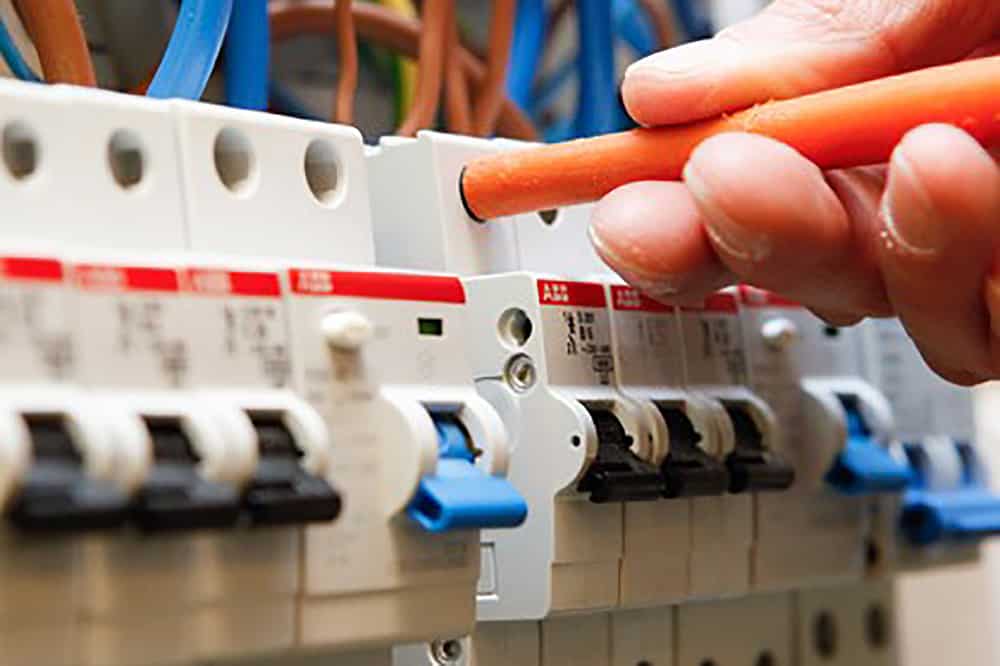

Hiring the right contractor

By carrying out regular electrical maintenance, you will foresee costly or dangerous situations. Electrical Systems are not often front of mind. You rarely walk past your wiring and notice frayed wires with a worn casing as they are usually locked away in cabinets. With regular maintenance, you will be able to identify these issues and have them repaired before they begin to affect the rest of your property.

If you want to explore electrical maintenance options for your business speak to the Usher Group, we will structure a plan and provide you with the best possible solution.